How far do you want to take your train performance?

The choice is yours

Recent technological advancements make it possible to extend train performance beyond what was recently thought to be the limit. Improvements in product reliability, technical upgrades in condition monitoring or the addition of machine learning and AI are developments that help you extend maintenance intervals and reduce the risk of unplanned stops, minimizing the total cost of ownership. By examining your needs and choosing a matching combination of solutions, you get the level of maintenance competitiveness, reliability, and lifecycle cost that your business demands.

Keep maintenance off your mind

There is always an SKF solution that meets your demands. If maintenance is not an issue for you, SKF solutions will make sure it stays that way.

Stay reliable

Reliability is a trademark for any SKF solution. By leaning on 100 years of experience in ensuring reliable rotation, you can be sure that you will achieve good uptime when you choose SKF products.

Access good value now and be prepared to advance further

Any SKF solution provides good value for money. And you can always advance your investment and push towards great or world-class performance by adding services and monitoring solutions at a later stage.

Extending maintenance intervals with confidence

A look at a proven SKF method that is used to extend maintenance intervals.

Condition monitoring is opening new frontiers for railway maintenance

An introduction to SKF condition monitoring in railways.

New business models and performance-based contracts in the railway industry

Get the most from your rolling stock by evolving how you purchase reliability and availability.

What SKF solutions do for you

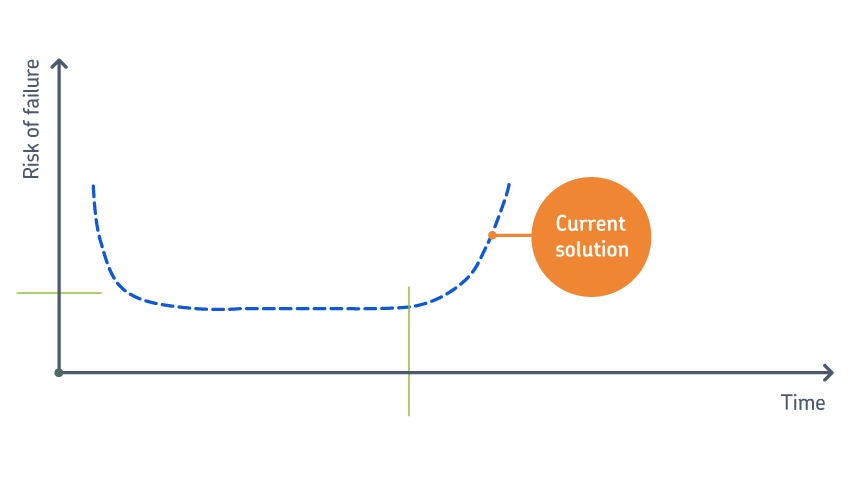

Early failures seldom depend on the bearing

The bathtub curve shows the typical life of bearings over time. If a bearing failure occurs, it often happens during the early part of their service life. This behaviour is called infant mortality and often depends on factors other than the bearing itself. Incorrect mounting is one common cause of failure at this stage.

It is essential to avoid failure during the useful life

After the infant mortality stage, the so-called useful life starts. Modern bearing technology usually offers a low, stable failure risk. However, even in this phase bearing failure does happen, resulting in extremely costly unplanned stops. Avoiding these is usually one of the top priorities for train operators and thus an essential factor in tender decisions.

Higher risk of failure near the end of bearing service life

Failure risk increases again as bearings near the end of their calculated life. This phase is called the wear-out phase.

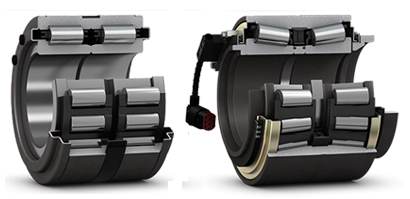

Bearings that take bearings out of the maintenance interval puzzle

SKF offers bearings for wheel-sets, gearboxes, traction motors and other applications for freight, metro, light rail or passenger trains or locomotives. For each application, you choose the features you need, and tailor your bearing solution to last as long as you need. Take a look at our latest design features, originally developed for very high-speed trains, or go to SKF.com for the entire portfolio of railway bearing solutions, including expertise in seals, lubrication and axleboxes.

Optimized grease retainer

A grease retainer that increases the quantity of grease in the bearing unit. It retains the lubricant in the bearing’s central area and releases oil to rolling contacts, ensuring optimum lubrication over an extremely long bearing lifetime.

What are the main challenges for train operators and train manufacturers today?

A recent survey among railway decision makers shows that the industry faces tough common challenges. Download your own copy of the report and learn all the details.

Make me more competitive

Learn more about how far you can take your train performance. Fill in the form to be contacted by an SKF representative.